Add to Cart

1. Application fields

Metal, metallurgical mining industry: aluminum powder, lead powder, copper powder, ore, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractories, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

Pollution treatment: waste oil, waste water, dyeing and finishing wastewater, auxiliaries, activated carbon and so on.

Chemical industry: resin, paint, industrial medicine, cosmetics, paint, traditional Chinese medicine powder, etc.

Food industry: powdered sugar, starch, salt, rice noodles, milk powder, soy milk, egg powder, soy sauce, fruit juice and so on.

2. Advantage and Features

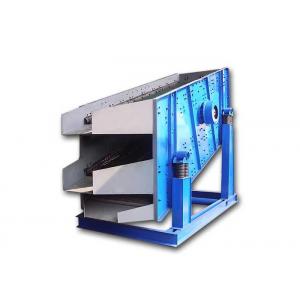

The circular track inertial vibrating screen can be used in various screening operations. Due to the circular vibration track of the screen surface, the materials on the screen surface are continuously turned over and loose, so the circular vibration screen has the following characteristics:

(1) large processing capacity and high screening efficiency.

(2) the vibrator adopts bearing thin oil lubrication and external block eccentric structure.

It has the characteristics of large exciting force, low bearing load, low temperature, low noise and so on.

The temperature rise of the bearing is less than 35 °.

(3) the vibrator is disassembled and disassembled as a whole, and the maintenance and replacement are convenient, which greatly shortens the maintenance cycle.

It only takes 1 to 2 hours to replace the vibrator.

(4) the side plate of the screen machine adopts whole plate cold work, no welding, high strength and long service life.

The connection between the crossbeam and the side plate adopts anti-torsion shear high-strength bolt connection, no welding, the crossbeam is easy to replace.

(5) the screen machine adopts rubber spring to reduce vibration, compared with metal spring, it has the advantages of low noise, long service life, stable over-resonance area, small dynamic load of each fulcrum and so on.

(6) the flexible coupling is used to connect the motor and the vibration exciter, which has the advantages of long service life and low impact on the motor.

A. the concrete foundation should be made according to the installation drawing before installation, and the flatness error of embedded anchor bolt or embedded steel plate is less than 3 mm.

B. After installation, check and adjust the springs at all levels so that the force of each support position is uniform, the axis of the motor should be 3-5 mm lower than the axis of the vibrator, and the support spring at the symmetry point should be horizontal (error < 3mm).

C, all parts of the screen machine should be firmly connected, all bolts should be fastened once before starting.

D. By adjusting the angle or weight of the eccentric block of the vibrator, the excitation force can be adjusted, so as to adjust the amplitude of the screen machine.

E. the distance between other obstacles is not less than 100mm.

| Model | Sieve Size | Feed Size | Capacity | Motor Model | Power | Measure (L*W*H) (mm) |

| YK1236 | 4.3 CBM | <200mm | 70-250t/h | Y160M-6 | 7.5KW | 3757*2364*2456 |

| 2YK1236 | 4.3 CBM | <200mm | 70-250t/h | Y160L-6 | 11KW | 3757*2364*2456 |

| 1. Material to be processed :_______ |

| 2. Max. granule size of the feeding material:______mm |

| 3. Handling capacity per hour:_______t/h |

| 4. Layer number:_______ |

| 5. Mesh size of each layer:______mm |

| 6. Bulk Density:_______t/cbm |

| 7. Material temperature:________℃ |

| 8. Working power supply: _____V ______HZ ______ph |