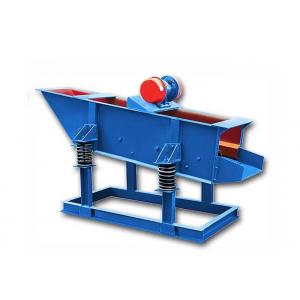

Anti Blocking Single Deck Vibrating Screen Easy Cleaning For Food Chemical Indstry

1. Applications

It is used for screening&grading of dry powder, fine particle and powder. Widely used in abrasive, building material, ceramic, fertilizer, food, pl astic, pharmaceutical, metallurgy industries, etc.

2. Brief Introduction

Linear vibrating screen is a high efficiency coarse screening equipment, using dual-motors as vibration source, making materials be tossed and move forward in a straight line on the screen surface. There are several balls on the bottom of the screen frame hit each other when vibrating, which can clear screen cloth and avoid blocking effectively.

4. Characteristics

- Suitable for high efficient coarse screening;

- Linear motion trail and large processing capacity;

- Simple structure, low power consumption, easy maintenance, all closed structure with the absence of dust disperse, adjustable screen surface inclinati

4. Matters needing attention

1. Once the machine on operation, the vibration part shall not be connected or contact with any object.

2. When feeding materials, pay attention to ensure the uniform feeding.

3. When the material through down, keeping no big impact to damage the screen.

4. Before operation and power off, there should no be any material on screen surface.

5. If there is any abnormal sound in the operation, the machine should be shutdown immediately and to check.

6. Ensure vibration motor maintenance regularly.

5. Driving Device Classification

- Dual Vibration motor driving

- Vibration exciter driving(for large model screen)

Tech Data

| Model | Screen Surface Size | Screen Cloth Aperture | Capacity | Vibration Frequency | Power | Screen Surface Inclination |

| (mm) | (mesh) | (t/h) | (r/min) | (kw) | (degree) |

| ZS-520 | 500*2000 | 2-325 mesh | ≤ 5 | 1460/960 | 0.4*2 | 0-10° |

| ZS-525 | 500*2500 | ≤ 8 | 0.55*2 |

| ZS-1020 | 1000*2000 | ≤ 12 | 1.1*2 |

| ZS-1025 | 1000*2500 | ≤ 16 | 1.1*2 |

| ZS-1030 | 1000*3000 | ≤ 20 | 1.5*2 |

| ZS-1224 | 1200*2400 | ≤ 23 | 1.5*2 |

| ZS-1525 | 1500*2500 | ≤ 28 | 2.2*2 |

| ZS-1530 | 1500*3000 | ≤ 32 | 2.2*2 |

How to get one set of linear vibrating screen separator? Only by telling us the following information for selection:

1. Material’s name, bulk density, and water content

2. Capacity you required___kg/h

3. What’s the purpose for our machine? Filtering, removing impurities or classification?

4. How many layers do you need?

5. The mesh size for each layer

6. Voltage and frequency

Service:

1. Special design offered.

2. Buyer label paste offered.

3. Sample testing support.

4. View our Factory

5. One year warranty.

6. Three years extended warranty.

7. 24 hours inquiry and consulting support.

8. Training how to instal and use the machine