Add to Cart

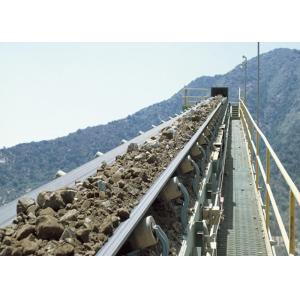

Working principle of Inclined Flat Belt Conveyor

TD75 belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved on them. The roller that drives the conveyor belt to rotate is called the driving roller (drive roller); the other roller that only changes the direction of the conveyor belt is called the redirecting roller. The driving roller is driven by a motor through a reducer, and the conveyor belt is dragged by the friction between the driving roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase traction and facilitate dragging. The material is fed from the feeding end, falls on the rotating conveyor belt, and is driven by the friction of the conveyor belt to be transported to the discharge end for discharge.

Feature of Inclined Flat Belt Conveyor

Strong adaptability to the line. The conveying line can be horizontal or inclined, or it can be bent horizontally or vertically, so it is less restricted by terrain conditions. Easy loading and unloading. The belt conveyor can be loaded and unloaded at any point according to the needs of the process.High reliability. Due to the simple structure and the light weight of the moving parts, as long as the conveyor belt is not torn, the service life can be as long as ten years, and the metal structural parts will not be damaged for decades if they are rust-proof. Less maintenance costs. The moving parts of the belt conveyor are only rollers and idlers, and the conveyor belt is very wear-resistant. Compared to other conveying machines, there are far fewer wear parts.

In addition, the belt conveyor also features low operating costs, low capital investment, low energy consumption, and high efficiency.

Application of Inclined Flat Belt Conveyor

Technical Parameters of Inclined Flat Belt Conveyor

| Belt Width | Section Form | Speed | Capacity |

| 650mm | Though | 0.8m/s | 131t/h |

| 1.0m/s | 164t/h | ||

| 1.25m/s | 206t/h | ||

| 1.6m/s | 264t/h | ||

| 2.0m/s | 323t/h | ||

| Flat | 0.8m/s | 67t/h | |

| 1.0m/s | 88t/h | ||

| 1.25m/s | 110t/h | ||

| 1.6m/s | 142t/h | ||

| 2.0m/s | 172t/h |

Selection Conditions of Inclined Flat Belt Conveyor

Material to be processed: _____

Handling capacity:_____

Bulk Density: _____t/m3

Material temperature: _____℃

Water content:____%

Material is corrosive or not: ____

Material is sticky or not: ____

Working environment temperature: ______ ℃

Working voltage:____V_____hz_____phase